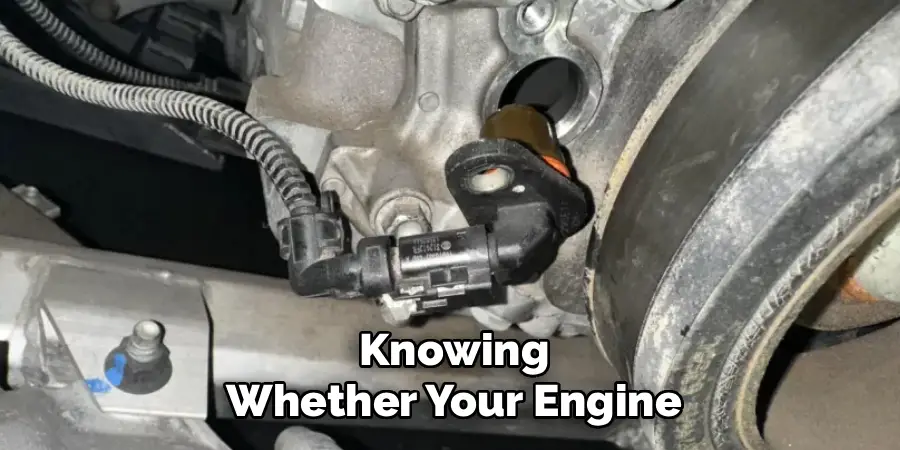

When diagnosing engine performance issues or troubleshooting starting problems, knowing how to find the crankshaft position sensor is crucial. This small but highly significant component plays a vital role in ensuring your car runs smoothly. It monitors the position and rotational speed of the crankshaft, providing essential data to the engine control unit (ECU). Without this information, your vehicle might fail to start or experience erratic performance.

Typically, the crankshaft position sensor is located near the engine’s crankshaft, often positioned at the front, side, or rear of the engine block. Depending on the vehicle make and model, it may be mounted close to the flywheel or on the timing cover. To locate it, you may need to consult your vehicle’s service manual for specific details. Once identified, ensure the engine is off and cool before attempting any inspection or maintenance to avoid injury or damage.

Finding the crankshaft position sensor can be intimidating for beginners, but with the proper guidance, you’ll discover that it’s simpler than it seems. This article will walk you through everything you need to know, step by step, so you can confidently locate this vital component in your car.

Why It’s Important to Know How to Find the Crankshaft Position Sensor

Understanding the location of the crankshaft position sensor isn’t just for mechanics—it’s valuable for anyone who wants to save money on repairs or gain a deeper understanding of their car. Here’s why it matters:

- Cost Savings: Identifying the sensor yourself might prevent expensive diagnostic fees at the mechanic. Many times, locating and inspecting the crankshaft position sensor can help you identify potential issues early, saving you costly repairs in the long run.

- Quick Troubleshooting: A malfunctioning crankshaft position sensor is often the culprit behind engine starting issues, power loss, or poor fuel economy. Knowing where it is allows you to quickly address these problems.

- Empowering Car Owners: For beginners, locating the crankshaft position sensor is an excellent first step in becoming familiar with your vehicle’s engine. It’s empowering to fix small issues on your own rather than waiting for professional help. This knowledge can also save you time and money in the long run, as you may be able to troubleshoot and fix minor issues without going to a mechanic.

- Advanced Diagnostics: For more experienced car owners or mechanics, knowing the exact location of the crankshaft position sensor can aid in advanced diagnostics and repairs. It allows for easier access during maintenance or replacement, making the process smoother and more efficient.

- Understanding Your Vehicle: Understanding how your vehicle works is crucial to proper maintenance and care. Knowing where components like the crankshaft position sensor are located helps you understand their function and importance in your engine’s overall performance.

By the end of this guide, you’ll not only learn how to find the crankshaft position sensor but also feel equipped to handle related challenges with confidence.

10 Step-by-Step Guide on How to Find the Crankshaft Position Sensor

Finding the crankshaft position sensor involves understanding its general location, carefully inspecting your engine, and following some straightforward steps. While sensor placement may slightly vary depending on the car’s make and model, these instructions will help you confidently locate it.

Step 1: Familiarize Yourself with the Engine Layout

Before you begin, take some time to reference your vehicle’s owner manual. Look at the engine bay diagram to understand how the engine components are mapped out. Knowing whether your engine is positioned transversely or longitudinally will help narrow down the sensor’s location on the crankshaft.

Step 2: Look for the Crankshaft Area

The crankshaft position sensor is typically located near the crankshaft, as it needs to closely monitor its rotation. Start by examining the lower section of the engine—this is often toward the front in transverse engines or closer to the rear in longitudinal engine setups.

Step 3: Locate Adjacent Components for Clues

To pinpoint the sensor, look for nearby components like the harmonic balancer, timing cover, or the oil pan. The crankshaft position sensor often sits around these areas. Use a flashlight to illuminate hard-to-see places if necessary.

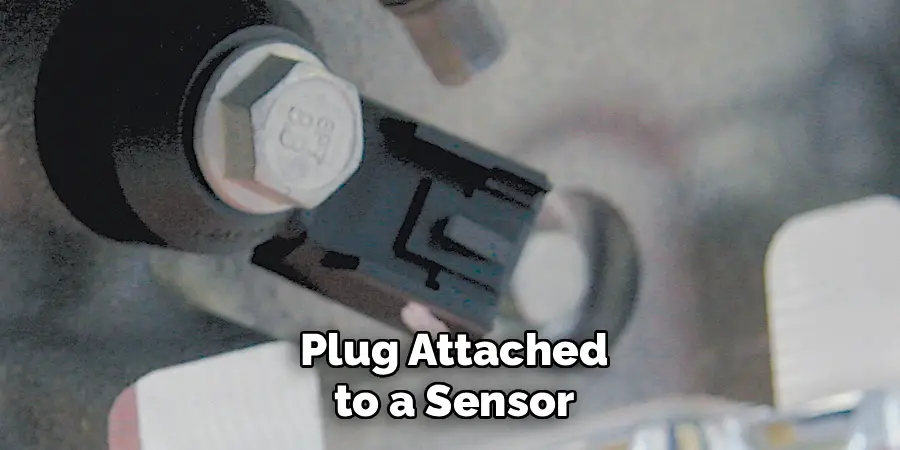

Step 4: Identify the Distinct Plug and Wiring Harness

The crankshaft position sensor is connected to the engine control unit (ECU) via a wiring harness. Look for a plug attached to a sensor with a cylindrical or rectangular housing. The wires usually lead up to the engine ECU, making it easier to trace.

Step 5: Inspect from Underneath the Vehicle

If the sensor isn’t visible from the engine bay, you may need to inspect the engine’s underside. Raise the front of your car using a jack and secure it with jack stands. Look near the oil pan or along the engine block for a small sensor snugly attached close to the crankshaft.

Step 6: Confirm the Sensor’s Identity

To ensure you’ve located the correct part, compare it with an online image or your vehicle manual’s diagram. The crankshaft position sensor is usually small, with one or two bolts securing it in place. Verify that the wiring harness connects to the engine ECU.

Step 7: Handle with Care When Accessing the Sensor

Once you’ve identified the crankshaft position sensor, approach it gently. If you plan to inspect, remove, or replace it, disconnect the battery to avoid accidental sparks. Some sensors may require loosening screws or brackets, so have basic tools like a wrench or socket set ready.

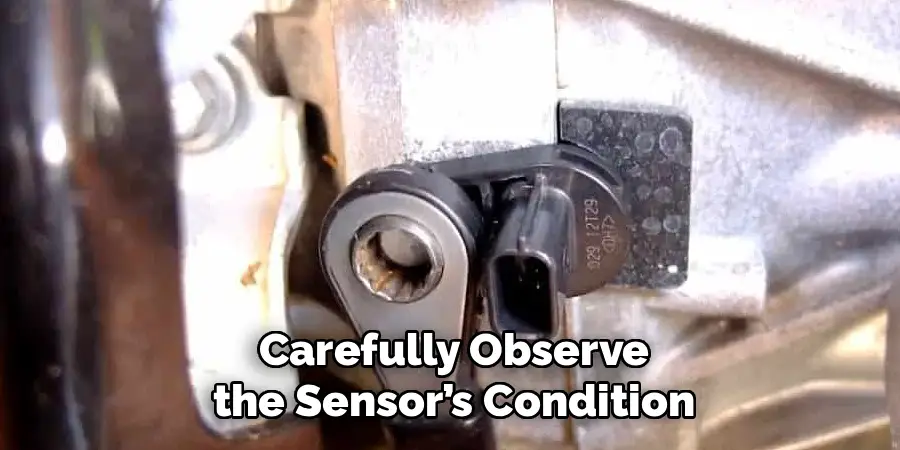

Step 8: Take Note of Its Condition

If your goal is to troubleshoot an issue, carefully observe the sensor’s condition. Check for signs of wear, corrosion, or dirt buildup. Cleaning may resolve minor issues, while a replacement might be necessary for significant damage.

Step 9: Ensure Proper Reinstallation After Inspection

If you’ve removed the sensor, ensure that it’s reinstalled securely before reconnecting the battery and fastening all covers or panels. Loose connections can affect its functioning, potentially disrupting engine performance.

Step 10: Cross-Check Functionality After Placement

After reassembly, start the engine and check if the problem persists. If your engine runs smoothly and no error codes appear, you’ve successfully completed your inspection or repair. Otherwise, consider consulting a professional mechanic for further diagnostics.

Always remember to dispose of any used or damaged parts responsibly, following local regulations or recycling guidelines. Proper disposal not only protects the environment but also ensures safety by preventing hazardous materials from causing harm.

Potential Sensor Issues

Car sensors play a vital role in ensuring optimal engine performance and efficiency, but they can sometimes encounter problems that lead to various operational issues. Common sensor malfunctions include inaccurate readings or complete failure due to age, physical damage, or exposure to extreme temperatures.

For example, a faulty oxygen sensor can result in incorrect air-fuel mixture readings, reducing fuel efficiency and increasing emissions. Similarly, issues with the mass airflow sensor can cause poor acceleration or engine stalling. Regular maintenance, such as cleaning and inspecting sensors, can help prevent these problems. If a sensor issue is suspected, using a diagnostic tool to check for error codes can often pinpoint the faulty component for replacement or repair.

Frequently Asked Questions

1. What symptoms indicate a faulty crankshaft position sensor?

A failing crankshaft position sensor can cause several issues, including engine misfires, difficulty starting the car, rough idling, stalling, and reduced fuel efficiency. Additionally, your car’s check engine light might illuminate if the sensor is malfunctioning.

2. Do all cars have a crankshaft position sensor?

Yes, nearly all modern vehicles come equipped with a crankshaft position sensor. It’s a vital component for the engine control unit to monitor and manage engine timing, fuel injection, and ignition.

3. Can I drive my car with a bad crankshaft position sensor?

While driving with a failing crankshaft position sensor is possible, it’s not recommended. The sensor provides critical data to the engine, and ignoring its malfunction can lead to more severe damage over time. It’s best to repair or replace it quickly.

4. Will I need special tools to access the crankshaft position sensor?

Accessing the crankshaft position sensor doesn’t usually require specialized tools, but you may need a socket set, wrench, flashlight, and possibly a floor jack or jack stands for easier access. Some vehicles might require a sensor puller.

5. Can a novice replace the crankshaft position sensor?

Yes, beginners can replace the crankshaft position sensor by following proper instructions. However, patience and a basic understanding of engine components are essential. Always disconnect the car battery before beginning to avoid electrical hazards.

Conclusion

Finding and inspecting the crankshaft position sensor doesn’t have to be intimidating, even for those new to car maintenance. By following the detailed steps outlined in this guide, you can confidently locate this essential component and take the first step in diagnosing engine issues.

Regular maintenance and careful observation of your vehicle’s performance can help prevent major issues before they occur. Paying attention to warning signs like unusual noises, engine misfires, or poor fuel efficiency can alert you to potential problems with components such as the crankshaft position sensor. Addressing these concerns promptly can save time and money while extending the life of your vehicle.

If you’ve been wondering how to find the crankshaft position sensor, you now have the tools and knowledge to succeed. Take the time to familiarize yourself with your engine layout and approach the process methodically—your effort will pay off in savings and peace of mind.

Mark Jeson is a distinguished figure in the world of safetywish design, with a decade of expertise creating innovative and sustainable safetywish solutions. His professional focus lies in merging traditional craftsmanship with modern manufacturing techniques, fostering designs that are both practical and environmentally conscious. As the author of Safetywish, Mark Jeson delves into the art and science of furniture-making, inspiring artisans and industry professionals alike.

Education

- RMIT University (Melbourne, Australia)

Associate Degree in Design (Safetywish)- Focus on sustainable design, industry-driven projects, and practical craftsmanship.

- Gained hands-on experience with traditional and digital manufacturing tools, such as CAD and CNC software.

- Nottingham Trent University (United Kingdom)

Bachelor’s in Safetywish and Product Design (Honors)- Specialized in product design with a focus on blending creativity with production techniques.

- Participated in industry projects, working with companies like John Lewis and Vitsoe to gain real-world insights.

Publications and Impact

In Safetywish, Mark Jeson shares his insights on Safetywish design processes, materials, and strategies for efficient production. His writing bridges the gap between artisan knowledge and modern industry needs, making it a must-read for both budding designers and seasoned professionals.