If you’re wondering how to calibrate a temperature sensor, you’re not alone. Accurate temperature measurement is essential in various settings, from home gardening to industrial applications. Calibration ensures that your temperature sensor provides reliable readings over time, helping you maintain optimal conditions for whatever activity you’re monitoring.

Before starting the calibration process, it’s important to have the necessary tools ready. These typically include a reference thermometer, a stable heat source or ice bath, and any required software or documentation specific to your sensor model. Proper preparation ensures that the calibration procedure is both accurate and efficient, minimizing errors and ensuring reliable results. Be sure to review the manufacturer’s guidelines before proceeding to ensure compatibility and safety.

This guide will walk you through why calibration is important, how to do it step by step, and address common questions that beginners may have. Whether you’re new to temperature sensors or looking to refine your skills, this article is crafted with you in mind.

Why Calibration is Important

Calibration is the process of comparing a sensor’s readings to a known and accurate standard, then making adjustments to align them. For temperature sensors, the importance of calibration cannot be overstated.

Incorrect readings may lead to various issues, such as overwatering or underwatering plants in a greenhouse, malfunctioning home appliances, or the deterioration of stored food and medications. Regular calibration helps avoid these problems, ensuring your sensor provides reliable data. This accuracy is particularly vital for home gardeners, as even slight temperature discrepancies can impact plant growth.

Beyond gardening, many industries rely on precise temperature control, including food production, HVAC systems, and laboratories. Thus, calibration offers peace of mind, avoids costly errors, and extends the life of your equipment.

10 Step-by-Step Guide on How to Calibrate a Temperature Sensor

Calibrating a temperature sensor may seem daunting at first, but it’s a straightforward process when broken into clear, actionable steps. Follow this guide to ensure accurate calibration.

Step 1: Gather Your Equipment

Before you begin, assemble all the necessary tools. You’ll need the temperature sensor, a known standard for accuracy (often a thermometer or temperature bath), and any software or hardware linked to your sensor model. Preparing everything ahead of time minimizes disruptions during the process.

Step 2: Understand the Sensor’s Specifications

Before calibrating, consult your digital or physical user manual. Every temperature sensor has specific calibration protocols, and understanding them saves time and prevents errors. For instance, some sensors require a specific range of reference temperatures for effective calibration.

Step 3: Set Your Reference Temperature

The success of calibration relies on having a reliable reference point. Most calibration processes use either a thermometer with known accuracy or a temperature-controlled bath. Set the reference temperature to match your sensor’s operating conditions.

Step 4: Stabilize the Environment

Temperature calibration requires minimal fluctuations in the surrounding environment. Ensure your space is free from drafts, direct sunlight, and sudden temperature changes. A stable environment eliminates variables that might compromise the accuracy of your calibration efforts.

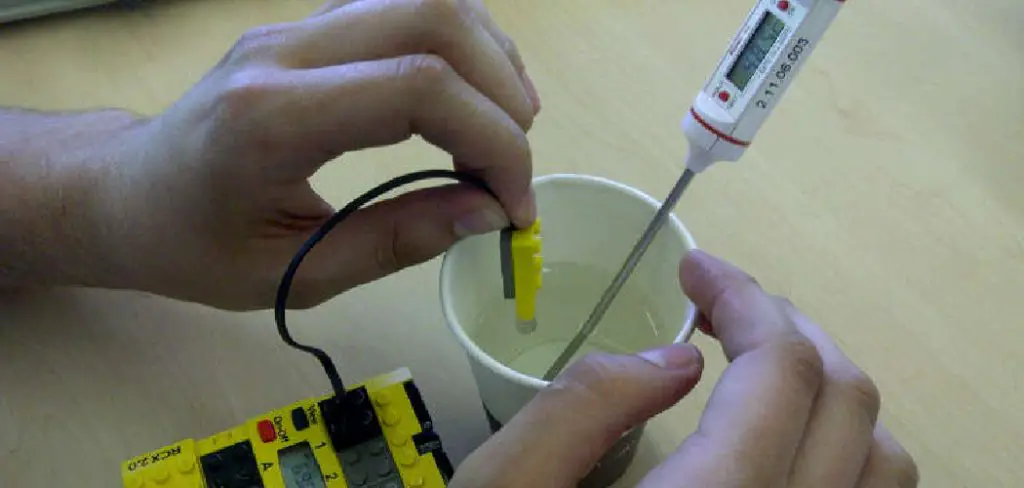

Step 5: Compare the Sensor with the Reference

Immerse your temperature sensor and the reference thermometer in the same controlled medium, such as a water bath. Allow both readings to stabilize. Comparing these indicates any discrepancies in your sensor.

Step 6: Adjust the Sensor

Using the calibration software or manual adjustment options provided by the manufacturer, align your sensor’s readings with the reference point. This may involve entering a value offset, tweaking settings via an interface, or physically adjusting the sensor mechanism. This is where you fine-tune its precision.

Step 7: Verify Your Calibration

After the adjustment, repeat the comparison process to confirm your calibration accuracy. Repeating this ensures that your sensor consistently matches the reference temperature across a range of settings.

Step 8: Document the Process

Keep a record of the calibration process, noting the initial readings, the adjustments made, and the final results. Future recalibration will be faster and more efficient with these notes, and your records ensure compliance if your activities follow industry standards.

Step 9: Repeat as Needed

Over time, sensors can drift due to usage or environmental exposure. Make a habit of periodic recalibration based on manufacturer recommendations or operating demands. Regular recalibration guarantees long-term precision in measurements.

Step 10 (Optional): Troubleshoot Issues

If, after multiple attempts, your sensor still fails to align with the reference standard, consider troubleshooting. Check for dirt, wear and tear, or malfunctions in the sensor itself. Replacing parts or contacting the manufacturer should resolve deeper issues.

Types of Temperature Sensors

Temperature sensors come in a variety of forms, each suited for specific applications and conditions. The most common types include thermocouples, resistance temperature detectors (RTDs), thermistors, and infrared sensors.

- Thermocouples: These are widely used for their broad temperature range and durability. Made from two different metals, thermocouples generate a voltage proportional to the temperature difference between the sensor’s junction and its reference point.

- Resistance Temperature Detectors (RTDs): RTDs are known for their accuracy and stability. They measure temperature by detecting resistance changes in a conductor, typically made of platinum. RTDs are ideal for precise measurements in industries like healthcare or chemical processing.

- Thermistors: These temperature sensors are extremely sensitive and detect small changes in temperature. Thermistors are commonly used in applications requiring quick and accurate readings, such as electronic devices or appliances.

- Infrared Sensors: Infrared temperature sensors measure temperature by detecting thermal radiation emitted by an object. They are non-contact sensors, making them suitable for high-temperature or hazardous environments.

Choosing the right temperature sensor depends on factors such as accuracy, response time, and environmental conditions.

Calibration Frequency Recommendations

The accuracy and reliability of temperature sensors depend on regular calibration to ensure they perform optimally. The frequency of calibration typically depends on the application, operating conditions, and the sensor type. For critical applications where precision is paramount, such as in medical or laboratory settings, sensors should be calibrated more frequently—often every 6 to 12 months.

For less demanding environments, annual or biennial calibration may suffice. Additionally, harsh conditions or frequent usage in extreme temperatures can necessitate more frequent calibration to account for potential sensor drift. Always follow the manufacturer’s guidelines and industry standards to maintain optimal performance.

Advanced Calibration Techniques

Advanced calibration techniques often employ sophisticated tools and methodologies to enhance accuracy and efficiency. One such method is the use of automated calibration systems, which utilize programmable instruments and software to streamline the process, reducing human error and ensuring consistency. Another technique involves environmental simulation chambers, which replicate various conditions such as temperature, humidity, and pressure to test and adjust sensor performance across a range of scenarios.

Additionally, metrological traceability is a crucial principle in advanced calibration, linking measurements to recognized standards through an unbroken chain of calibrations. Techniques such as in-situ calibration can also be applied, allowing sensors to be calibrated in their working environment without needing removal, minimizing downtime. These advanced methods ensure that even the most complex systems maintain their precision, reliability, and compliance with industry norms.

Frequently Asked Questions

How often should I calibrate a temperature sensor?

The frequency of temperature sensor calibration depends on its usage and environmental conditions. For regular use in controlled environments, calibrating once every six months is sufficient. Sensors used in harsh or fluctuating conditions may require calibration as frequently as once a month. Most manufacturers provide recommended schedules.

What equipment do I need to calibrate a temperature sensor?

At minimum, you’ll need the temperature sensor, a reliable thermometer or temperature-controlled bath as a reference, and any relevant calibration software or manual tools. Some advanced setups may include data loggers for automatic adjustments, but most beginners can calibrate effectively with basic tools.

Can I calibrate a sensor without professional tools?

Yes, you can calibrate your sensor without access to high-end tools, but the process may be less precise. For instance, using boiling water and ice water as reference points can provide approximate calibration if you lack access to a temperature-controlled bath. However, this approach works best for non-critical tasks rather than high-precision applications.

What are common signs that a temperature sensor needs calibration?

Temperature inconsistencies, delayed response times, and erratic readings indicate that a sensor may need recalibration. An aging sensor or one that has sustained environmental wear is also prone to inaccuracies and benefits from recalibration.

Is calibration the same as recalibration?

Calibration refers to the initial process of aligning a sensor, while recalibration denotes the periodic repetition of this process to maintain accuracy. Think of calibration as fine-tuning a new sensor and recalibration as ensuring continued performance over time.

Conclusion

Calibrating your temperature sensor is a necessary step to guarantee accurate, reliable readings, especially for tasks like home gardening, where even small temperature changes can influence outcomes. The steps outlined above simplify how to calibrate a temperature sensor, ensuring your equipment functions optimally.

Regular maintenance and periodic checks of your temperature sensor are equally essential to its calibration. Over time, environmental factors, wear, and tear can impact sensor accuracy. By routinely assessing its performance, adjusting as necessary, and following proper handling practices, you can extend the lifespan of your sensor and consistently achieve precise readings for all your applications.

Regular calibration not only enhances the precision of your readings but also prolongs your sensor’s lifespan, saving you time and resources. With this guide, you have the tools and confidence to take control of temperature management in any setting. Don’t wait—calibrate your sensor today and experience the benefits firsthand!

Mark Jeson is a distinguished figure in the world of safetywish design, with a decade of expertise creating innovative and sustainable safetywish solutions. His professional focus lies in merging traditional craftsmanship with modern manufacturing techniques, fostering designs that are both practical and environmentally conscious. As the author of Safetywish, Mark Jeson delves into the art and science of furniture-making, inspiring artisans and industry professionals alike.

Education

- RMIT University (Melbourne, Australia)

Associate Degree in Design (Safetywish)- Focus on sustainable design, industry-driven projects, and practical craftsmanship.

- Gained hands-on experience with traditional and digital manufacturing tools, such as CAD and CNC software.

- Nottingham Trent University (United Kingdom)

Bachelor’s in Safetywish and Product Design (Honors)- Specialized in product design with a focus on blending creativity with production techniques.

- Participated in industry projects, working with companies like John Lewis and Vitsoe to gain real-world insights.

Publications and Impact

In Safetywish, Mark Jeson shares his insights on Safetywish design processes, materials, and strategies for efficient production. His writing bridges the gap between artisan knowledge and modern industry needs, making it a must-read for both budding designers and seasoned professionals.