The crankshaft position sensor is a crucial component of your vehicle’s engine management system. It monitors the position and rotational speed of the crankshaft, providing data to the engine control unit (ECU) to ensure proper timing for fuel injection and ignition.

When this sensor malfunctions, it can lead to a range of performance issues, including poor engine performance, stalling, or failure to start. Identifying the signs of a bad crank sensor early on can save you time and potentially costly repairs. In this blog post, we’ll walk you through the steps on how to tell if crank sensor is bad so that you can get back to using it in no time! So grab your tools, and let’s get started!

What Is a Crankshaft Position Sensor?

A crankshaft position sensor, often referred to as a crank sensor, is a key component of a vehicle’s engine management system. Its primary function is to monitor the position or rotational speed of the crankshaft. The data gathered by the crank sensor is sent to the Engine Control Unit (ECU), which uses this information to optimize fuel injection and ignition timing. This ensures that the engine operates efficiently and performs as expected. Without a functioning crankshaft position sensor, the ECU cannot accurately control these critical processes, leading to issues such as misfires, stalling, and reduced fuel efficiency. The sensor plays a crucial role in modern engines, where precision and smooth operation are paramount for performance and emissions control.

Importance of the Crankshaft Position Sensor

The crankshaft position sensor plays a critical role in the functioning of your vehicle’s engine. It monitors the position and rotational speed of the crankshaft, sending this data to the engine control unit (ECU). This information is essential for ensuring precise fuel injection and ignition timing, which are vital for optimal engine performance and efficiency. Without a properly functioning crankshaft position sensor, the engine cannot operate smoothly, leading to issues like misfires, reduced fuel economy, and even engine failure. Understanding the importance of this sensor highlights why timely diagnosis and repair are crucial to maintaining your vehicle’s reliability and longevity.

Common Symptoms of a Bad Crank Sensor

A failing crankshaft position sensor can manifest through several noticeable symptoms, which, if addressed promptly, can prevent further engine damage. Some of the most common signs include:

- Engine Misfires – Irregular signals from the sensor can lead to inconsistent spark timing, causing the engine to misfire or run roughly.

- Difficulty Starting – Without accurate data from the sensor, the ECU may struggle to determine the correct timing for ignition, resulting in hard starts or a failure to start altogether.

- Stalling – A faulty crank sensor can cause the engine to stall unexpectedly while driving, creating a safety concern.

- Check Engine Light – When the sensor malfunctions, the ECU often triggers the check engine light, signifying an issue that requires attention.

- Reduced Power or Acceleration – Incorrect data from the crank sensor can lead to poor engine performance, noticeable through sluggish acceleration or reduced power output.

Recognizing these symptoms early and consulting a qualified technician can help mitigate severe engine damage and ensure continued reliability of your vehicle.

10 Methods How to Tell if Crank Sensor Is Bad

1. Watch for Engine Cranking Without Starting

One of the most common signs of a failing crankshaft position sensor is an engine that cranks but refuses to start. This occurs because the ECU relies on accurate crankshaft data to determine the exact moment to fire the spark plugs and inject fuel. Without a signal from the crank sensor, the ECU is essentially blind to engine position and will not initiate combustion. If your vehicle turns over consistently but fails to start—even with good battery voltage and fuel—it is a strong indication the crank sensor might be bad or not communicating with the ECU.

2. Observe Engine Stalling While Driving

A malfunctioning crank sensor may cause the engine to stall intermittently or completely shut off while the vehicle is in motion. This happens when the sensor signal suddenly drops or fluctuates, causing the ECU to lose track of the crankshaft’s position. The engine may shut off unexpectedly and then restart after a few moments or refuse to start again until the sensor cools down. If your vehicle cuts out randomly while driving, especially without triggering warning lights, a failing crank sensor could be the underlying cause.

3. Monitor the Check Engine Light and Retrieve Diagnostic Codes

When the crank sensor malfunctions, it often triggers the Check Engine Light (CEL). Using an OBD-II scanner, you can read the diagnostic trouble codes (DTCs) that may be stored in the ECU. Common codes related to crank sensor issues include P0335 (Crankshaft Position Sensor “A” Circuit Malfunction) and P0336 (Crankshaft Position Sensor “A” Range/Performance). These codes indicate the ECU has detected problems with the crank sensor signal. While not definitive proof, these codes offer a reliable starting point for further inspection and testing of the crank sensor system.

4. Check for Engine Misfires or Rough Idling

A faulty crankshaft position sensor can disrupt engine timing, leading to misfires, rough idling, or erratic acceleration. The sensor’s primary job is to synchronize ignition and fuel injection with the engine’s mechanical movements. When this data is inaccurate or delayed, it can throw off the entire combustion cycle.

If your engine idles roughly, struggles to maintain RPMs, or misfires under acceleration without clear fuel or spark issues, the crank sensor should be evaluated. These symptoms are especially telling when accompanied by performance loss or stalling.

5. Use a Multimeter to Test Sensor Resistance

Testing the crank sensor with a digital multimeter is a reliable way to assess its health. Begin by disconnecting the sensor’s electrical connector. Set the multimeter to the ohms (Ω) setting, and place the probes on the sensor terminals. Consult your vehicle’s service manual for the correct resistance range—commonly between 200 and 2,000 ohms. If the reading is significantly outside this range or shows as “OL” (open loop), the sensor may be defective. Note that this test is most accurate for sensors that use a magnetic or inductive pickup.

6. Inspect the Sensor for Physical Damage or Metal Shavings

Sometimes, the issue is not electrical but physical. Remove the crank sensor and visually inspect it for cracks, corrosion, or damage to the sensor tip. Check for the presence of metal shavings on the magnetic tip, which may indicate excessive engine wear or debris interfering with signal generation. These contaminants can distort the sensor’s magnetic field and cause signal loss. Cleaning the sensor may temporarily restore function, but if damage is present, replacement is the safest and most reliable option.

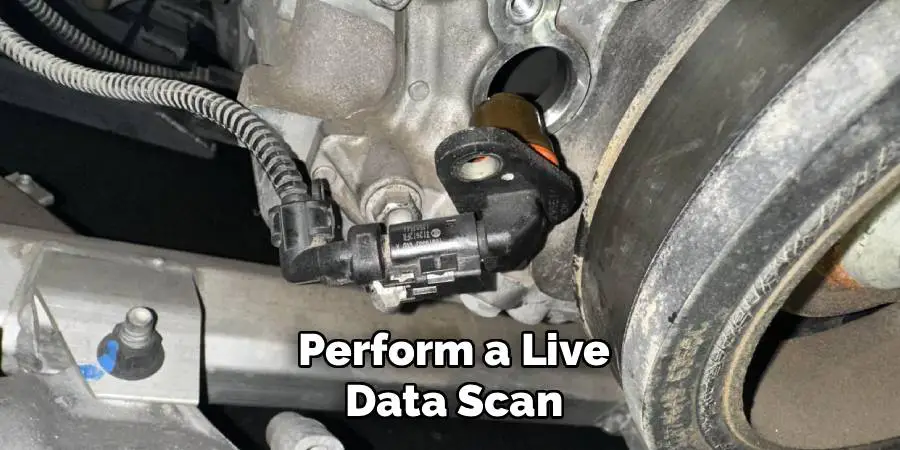

7. Perform a Live Data Scan with a Diagnostic Tool

Advanced OBD-II scan tools with live data functionality can monitor the crank sensor in real-time. While the engine is cranking or running, observe the RPM data stream on the scan tool. If no RPM signal is detected while cranking, it is a strong indication that the crank sensor is not working or its signal isn’t reaching the ECU. Even if the sensor is physically intact, internal failures or broken wiring can prevent signal transmission. Real-time data is one of the most accurate ways to confirm sensor failure.

8. Listen for Delayed or Hard Starting Issues

Hard starting, especially when the engine is warm, can be another indicator of a faulty crank sensor. Heat-related failure is a common trait; the sensor may function correctly when cold but lose signal when the engine reaches operating temperature. This happens due to expansion of internal components, wiring fatigue, or signal dropout. If your engine starts normally in the morning but cranks excessively or fails to start when hot, consider testing or replacing the crank sensor as part of your troubleshooting.

9. Inspect the Wiring and Connector Leading to the Sensor

Before assuming the sensor itself is defective, check the wiring harness and connector for signs of wear, corrosion, or loose contact. Engine vibration, heat, and age can damage wiring insulation, leading to short circuits or open connections. Use a multimeter to verify continuity from the sensor plug to the ECU pin. If the wires test good and there’s no visible damage, it helps narrow the problem down to the sensor or the ECU. Replacing a good sensor without checking the wiring first can result in wasted time and money.

10. Conduct a Crank Sensor Oscilloscope Test for Signal Pattern

For advanced diagnostics, using an oscilloscope to analyze the crank sensor waveform is the most definitive method. Connect the oscilloscope to the signal wire and crank the engine. A good crank sensor will produce a clean, consistent waveform with evenly spaced pulses.

Irregular or missing pulses indicate a faulty sensor or damaged reluctor wheel (toothed wheel on the crankshaft that the sensor reads). This test requires experience and professional-grade equipment but offers precise insight into the sensor’s real-time behavior and interaction with engine mechanics.

Conclusion

A bad crankshaft position sensor can manifest in various frustrating symptoms, from hard starts and misfires to stalling and check engine lights. Using a blend of observation, diagnostic scanning, resistance testing, and live data analysis can help confirm the sensor’s condition. Thanks for reading our blog post on how to tell if crank sensor is bad! We hope you found it helpful and informative.

Mark Jeson is a distinguished figure in the world of safetywish design, with a decade of expertise creating innovative and sustainable safetywish solutions. His professional focus lies in merging traditional craftsmanship with modern manufacturing techniques, fostering designs that are both practical and environmentally conscious. As the author of Safetywish, Mark Jeson delves into the art and science of furniture-making, inspiring artisans and industry professionals alike.

Education

- RMIT University (Melbourne, Australia)

Associate Degree in Design (Safetywish)- Focus on sustainable design, industry-driven projects, and practical craftsmanship.

- Gained hands-on experience with traditional and digital manufacturing tools, such as CAD and CNC software.

- Nottingham Trent University (United Kingdom)

Bachelor’s in Safetywish and Product Design (Honors)- Specialized in product design with a focus on blending creativity with production techniques.

- Participated in industry projects, working with companies like John Lewis and Vitsoe to gain real-world insights.

Publications and Impact

In Safetywish, Mark Jeson shares his insights on Safetywish design processes, materials, and strategies for efficient production. His writing bridges the gap between artisan knowledge and modern industry needs, making it a must-read for both budding designers and seasoned professionals.