Are you looking for an easy way to securely fasten two parts together? Camlock systems may be the answer! But what are camlocks, and how do they work?

This blog post will not only explain exactly what a camlock system is but will also provide step-by-step instructions on how to use camlock so that you can get your components connected quickly and safely. Whether you’re in a rush or just want added peace of mind, now is the perfect time to learn about this handy product: Discover the durability of cam locks with us today!

What is a Camlock?

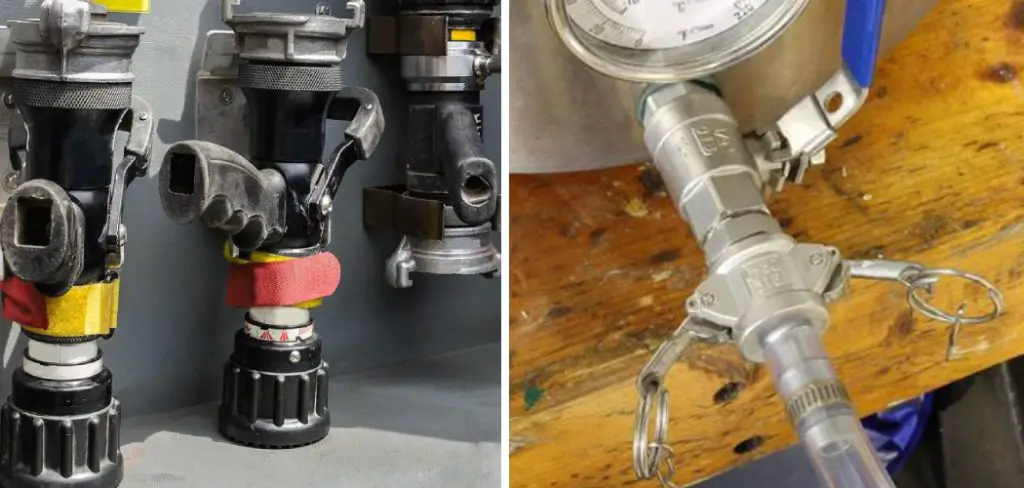

A camlock is a type of quick-connecting system used to securely fasten two parts together. It works by inserting the male connector into the female receiver, then turning the key or lever until it clicks into place, locking both components in an airtight manner.

The cam lock offers more security than traditional methods such as screws, bolts, or nails. It also takes only a fraction of the time to assemble and disassemble.

Step-by-step Guidelines on How to Use Camlock

Step 1: Familiarize Yourself with the Camlock

Before you even begin to put the camlock together, it is important that you familiarize yourself with the product. Take a moment to examine the key or lever and understand how it works. The male connector should have a “T” shape, while the female receiver will look like an open-mouthed cup.

Step 2: Prepare the Connectors

Make sure that the connectors are clean and free of any debris or dirt before assembly. This will ensure a proper connection once the cam lock is in place. If needed, use a damp cloth to wipe off the surfaces of each connector. Preparing the connectors is the most important step in learning how to use a camlock.

Step 3: Insert Connectors

Once the connectors are prepared, it’s time to insert them into each other. Start by aligning the male connector with the female receiver and pushing it into place until you hear a click. This indicates that the two components are now properly connected. While inserting the connectors, make sure that you keep them in the same position to ensure a secure connection.

Step 4: Tighten the Connectors

The next step is to tighten the connection. This can be done by turning the key or lever clockwise until you hear a clicking sound. The goal here is to ensure that both parts are firmly locked together. Once this step is complete, your camlock system should be secure and ready for use.

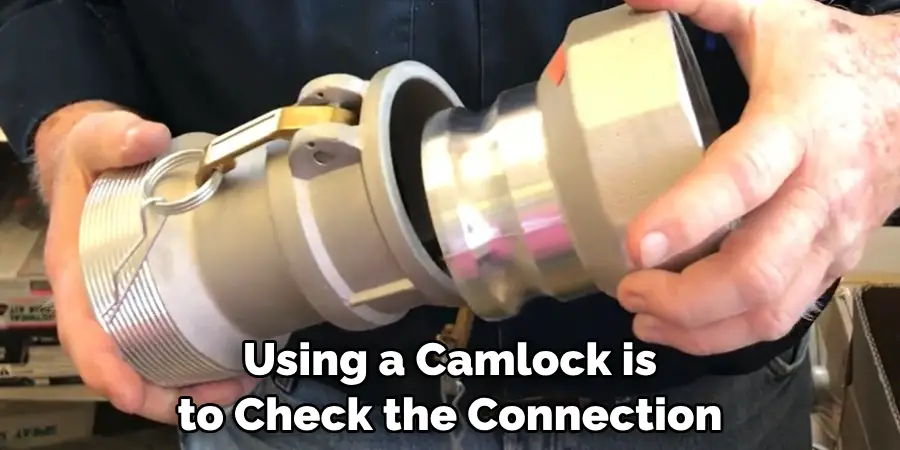

Step 5: Check the Connection

The final step in using a camlock is to check the connection. This can be done by gently tugging on both connectors. If there is any movement or loosening of the connection, you may need to tighten it further. Once you are satisfied with the connection, your camlock system is ready to use.

Following these steps will help you safely and efficiently assemble a camlock system. Camlocks can provide secure connections in a wide variety of applications, such as industrial machinery, medical equipment, and outdoor equipment.

With the ease and durability that cam locks offer, you’ll never have to worry about parts coming loose or components slipping apart. Give them a try today for added peace of mind!

Additional Tips and Tricks to Use Camlock

1. To prevent the camlock from becoming loose, you should check to make sure it is tightened properly after each use.

2. If the camlock is used in a wet environment, it is important to check for signs of corrosion or wear and tear regularly.

3. It is also recommended that you apply some kind of lubricant to the parts where two components of the camlock join together. This will ensure smooth operation and reduce wear and tear.

4. If you need to remove a camlock, make sure that you use an appropriate tool designed for the job, such as a wrench or pliers. Do not use force or leverage in order to try and move the lock, as this could cause damage.

5. Make sure to store your camlock in a safe and dry place when not in use. Exposure to moisture or extreme temperatures could damage the lock over time.

6. If you need to purchase replacement parts for your camlock, make sure that they are compatible with the type of lock you have before buying them. Different varieties of locks may require different types of components, so be sure to research this before making any purchases.

7. Finally, make sure to follow the manufacturer’s instructions when using and maintaining your camlock. This will ensure that it remains in good condition and works as intended for a long time.

8. Regular maintenance is key when using a Camlock – check all components of the lock annually or whenever you feel it is necessary. This will help to ensure that the lock performs optimally and provides secure fastenings for a long time.

9. Additionally, investing in high-quality cam locks from trusted manufacturers is recommended. While they may be more expensive than other options, they are usually much more durable and reliable in the long run.

Following these tips and tricks can help you get the most out of your cam lock and ensure that it remains secure and reliable for many years to come.

Things You Should Consider to Use Camlock

- Make sure all the components of your system are compatible with Camlock. The manufacturer should specify this in its instructions or on its website.

- Check that you have enough space for any additional parts recommended by the manufacturer to be installed. This could include mounting brackets, seals, and other accessories.

- Consider how many locks you need for each application – most will require two locks, but some applications may need more.

- Research what type of Camlock is best suited for your application – there are various sizes, types, and locking mechanisms available.

- Choose a quality lock with high-security features to protect against tampering or theft.

- Check that the materials used for the cam locks are able to withstand extreme temperatures and other environmental conditions that may be experienced in the application.

- Consider if you need access to the components without unlocking them, as some camlocks offer a secondary security feature such as a keyless entry system or combination lock.

- If you’re using Camlock on an outdoor installation, make sure it is corrosion-resistant and waterproof.

- When installation is complete, always test the system to make sure it works correctly.

- Regularly inspect your Camlock for signs of wear and tear, and replace or repair as soon as any issues are found. This will help ensure optimum performance and security.

Following these considerations will help you make the most of Camlock and ensure its longevity. With proper usage, your system should function effectively for years to come.

Safety When Using Camlock

When using camlocks, it is important to always follow safety protocols to avoid potential injuries or other hazardous situations. Here are a few tips to keep in mind:

- Wear protective gear, such as gloves and safety glasses, when handling the cam locks.

- Read the manufacturer’s instructions carefully before starting any work with Camlock.

- When cutting or drilling into a system for installation purposes, be sure to have an appropriate dust and particulate collection system in place.

- Always make sure that all components are securely fastened before operating the system.

- To avoid tampering, store Camlocks in a secure place when not in use.

- Do not exceed the recommended load limits on the camlocks. This can cause damage and can even be dangerous if heavy items are left suspended by the locks.

- Regularly inspect all components to make sure they are in good condition.

By following these tips, you can ensure a safe and secure installation of your Camlock system. Proper maintenance will help extend the life of the locks and keep your system functioning efficiently.

Frequently Asked Questions

How Do I Connect a Camlock Fitting?

Camlock fittings are easy to use and don’t require any tools for assembly. To start, insert the male half of the fitting into the female half until it clicks in place. Once both halves are connected, secure them together with an optional locking lever or safety clip. Make sure there is no leakage when connecting Camlock fittings as this can cause damage to the fitting and potential hazards.

What Are the Different Types of Camlock Fittings?

Camlock fittings come in a variety of materials, sizes, and types. Aluminum, stainless steel, brass, and polypropylene are just some of the materials available. Type A camlocks are the most common and feature a male groove adapter, while type B camlocks have a female groove adapter. Type C camlocks have a male and female thread while type D camlocks feature both a male and female flange.

Do Camlock Fittings Need to Be Secured?

Yes, always make sure to secure your Camlock fittings, as this will prevent them from coming apart due to vibration or pressure. An optional locking lever or safety clip can be used for added security. Additionally, you should always check for leaks when connecting Camlock fittings as this can cause potential hazards.

What Is the Maximum Working Pressure of a Camlock Fitting?

The maximum working pressure of Camlock fittings depends on the material used. Generally, aluminum fittings have a maximum working pressure of 150 psi, brass fittings have a maximum working pressure of 200 psi, and stainless steel fittings have a maximum working pressure of 350 psi.

Conclusion

Now you know how to use camlock fittings, the different types available, and the maximum working pressure of each material. Always make sure to secure your fittings using an optional locking lever or safety clip and check for any leakage before use. With this knowledge in hand, you can confidently install Camlock fittings with ease.